ABCR

Automated Gun Barrel Inspection and Cleaning Robot

Watch Video

1.45 Mins

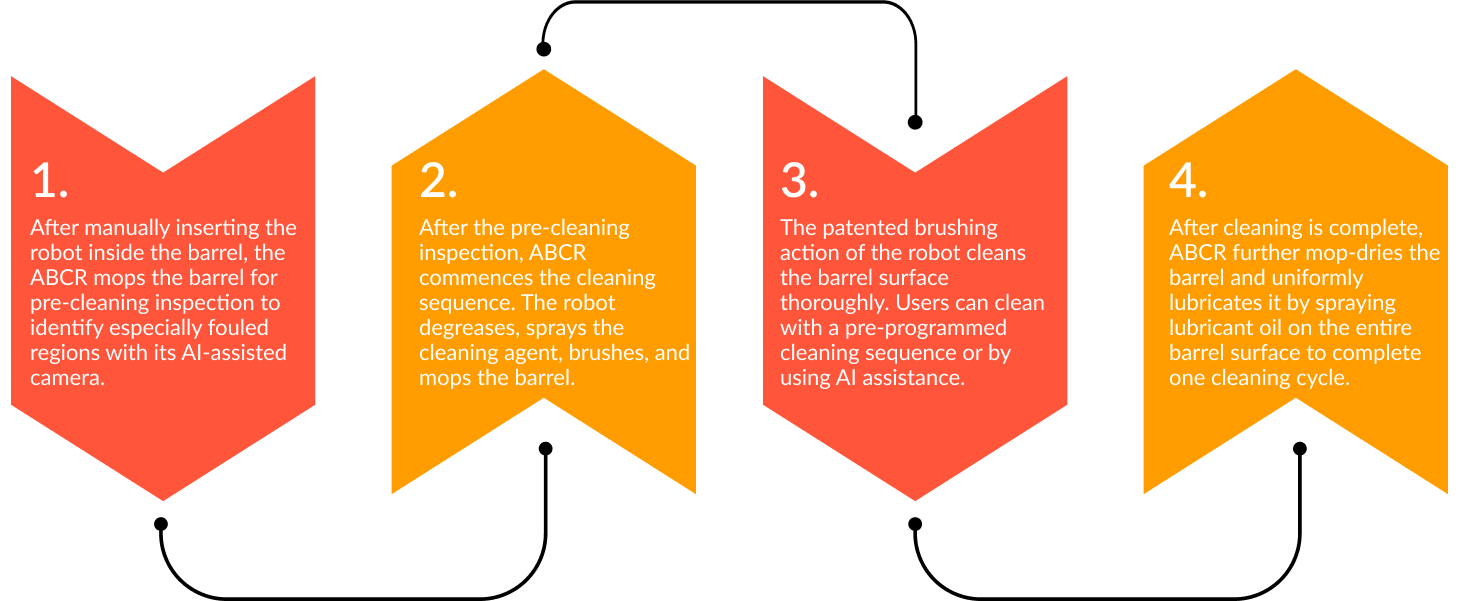

The Automated Gun Barrel Cleaning and Inspection Robot is a novel cleaning and inspection system designed, developed, and manufactured in India. The system can automatically crawl, clean, and inspect large caliber gun barrels. This modular cleaning system provides superior cleaning quickly, eliminating manual cleaning efforts. The robotic gun cleaning system removes carbon deposits, copper fouling, and post-combustion residues. ABCR also lubricates the barrel surface to safeguard it from corrosion. In the fully automated mode, it inspects and localizes uncleaned patches inside the barrel using its AI-powered camera and automatically cleans it, ensuring thorough cleaning. The system is suitable for both smooth and rifled gun barrels.

Features

Fully Automated Operation

Crawls, brushes, mops, and lubricates gun barrels

Effortless Cleaning

Superior & quick cleaning, eliminating manual efforts

AI-powered Vision Inspection

Inspects, detects, and localizes uncleaned patches and surface defects

Compact Design

Suitable for both smooth and rifled barrels

Key Features

Crawls, brushes, mops, and lubricates gun barrels

Superior & quick cleaning, eliminating manual efforts

Inspects, detects, and localizes uncleaned patches and surface defects

Suitable for both smooth and rifled barrels

Crawls, brushes, mops, and lubricates gun barrels

Superior & quick cleaning, eliminating manual efforts

Inspects, detects, and localizes uncleaned patches and surface defects

Suitable for both smooth and rifled barrels

Working of the System

Gallery

Utility Benefits of ABCR

- The ABCR can clean barrels in a matter of hours as opposed to days it takes with conventional cleaning methods.

- This system requires only two men to load and unload the bot and only one while operating the system, as opposed to six to eight men needed for manual cleaning.

- ABCR’s modular design allows users to change brushes or other parts quickly as needed.

- The high-torque motors in the robot allow high levels of control over the motion and cleaning force required during simultaneous locomotion and brushing.

- The robot is programmed with AI capabilities, allowing it to operate independently without human intervention. Users can easily switch to manual mode and operate the robot if human operation is needed.

- The system’s onboard camera allows users to track the progress of the cleaning process in real-time, allowing them to make decisions on the go.

- ABCR can run on available AC and DC power or on a battery with up to 24 hours of backup, providing extreme operational flexibility on the field.

The Phoenix Group® Homepage

The Phoenix Group® Homepage