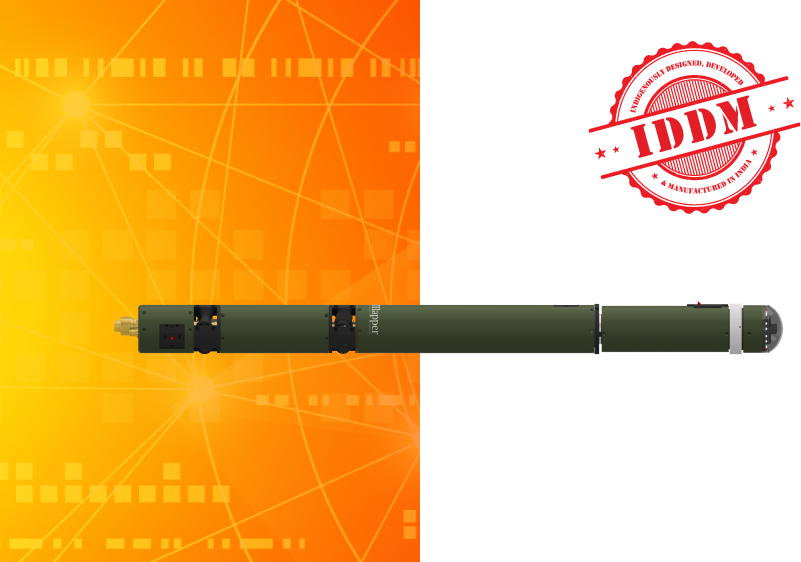

Laser Inspection Robot

Powerful Robotic System For Gun Barrel Inspection

AI-powered Robotic Inspection Solution for Guns, Torpedo & Rocket launcher tubes

The Robot is a modular system equipped with cutting-edge technology, incorporating an onboard camera and an advanced LASER system. Through its meticulous examination, it generates comprehensive analytical reports, providing you with an in-depth assessment of the barrel’s health and serviceability.

Features

Fully Automated Operation

Automatically determine serviceability of barrel

Data-driven

Inspection data with micron-level precision.

AI-powered Inspection

Detect defects flawlessly, and automatically

Versatility

Supports smooth and rifled barrels

Manual & Automatic Modes of Operation

Flexibility to suit your needs

Key Features

Automatically determine serviceability of barrel

Inspection data with micron-level precision

Detect defects flawlessly, and automatically

Supports smooth and rifled barrels

Flexibility to suit your needs

Automatically determine serviceability of barrel

Inspection data with micron-level precision

Detect defects flawlessly, and automatically

Supports smooth and rifled barrels

Flexibility to suit your needs

Utility Benefits

The Laser Inspection Bot provides critical data to quantify the barrel health for data-driven decisions by giving objective data.

- The system maintains the history of camera images, LASER Scan data, and analytical reports from inspections

- Only one user can load, unload, and control the system

- Perform inspections confidently with AI-driven scanning powering the camera and the LASER system

- Users can choose between manual and automatic modes as per requirement and ease of use

- The camera’s live stream lets users see, control, and adjust operations in real-time

- The robot can run on AC and DC power with up to 24h of battery backup for operational flexibility.

Gallery

Specifications

76mm Gun Barrels, 213mm IRL & 536mm Torpedo

Crawling and Inspection System (Ø X L)

- 76mm x 1000mm (SRGM)

- 213mm x 625mm (IRL)

- 536mm x 750mm (TORPEDO)

Crawling and Inspection System

- 7 Kg (SRGM)

- 20 (IRL, TORPEDO)

Inspection Mechanism

Visual inspection using video live stream 2 MP camera CMOS sensor, LASER profiler

No. of Persons Required

Loading & Unloading: 1

Operation: 1

Inspection Modes Supported

Manual mode, Automatic mode

Travel Speed Range

0.01 mm/sec to 10mm/sec

Ruggedized Controller

- Portable computerized controller with a rugged enclosure and in-built display, water and dustproof keypad and joystick designed to operate in harsh environments

- High-speed, industrial-grade CPU with 8GB RAM, GPU, and 2TB solid-state memory storage

Display

- 2000 nits’ brightness

- 15-inch

- Sun readable

- Anti-glare rugged display with backlight

- Min. pixel resolution: 1024×786

- Display colors: 16.2M/262K

Interface

- 1 ethernet port (1 Gbps data transfer)

- 1 USB port

- 24VDC or 230VAC with AC-DC Adapter

Environmental Conditions to be Supported

- Operating temperature: 0oC to 50oC

- Storage temperature: -20oC to 65oC

- Operating humidity: 60% RH

- Operating humidity: 90% RH while stored inside the storage casing

More Specifications

The Phoenix Group® Homepage

The Phoenix Group® Homepage